CNC Turning and milling

In our turning department we employ six state of the art CNC machines, allowing both bar and second operation turning. The milling department has 3 workstations with integrated CAD-Cam and 4th axis table.

Consulting and Design

Experience and technical expertise allow our company to collaborate with our customers in order to optimize every step of the production process. The verification of the quality requirements takes place both during the production process and at the end of it.

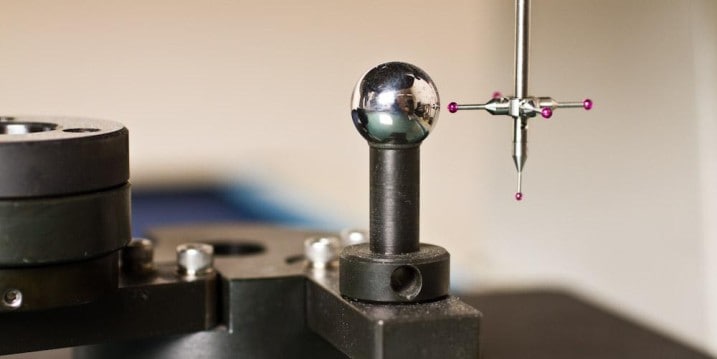

Metrology

The new metrology room that operates under the “Precision Inside” brand is an innovative service offered to our customers. Precision measurements, prototyping, reverse engineering and many new services.

Cutting edge Technology

Lathes and numerical control machining centers of the latest generation for a machine fleet in constant evolution and updating

Industry 4.0

Our production and management model is updated according to the standards of the modern “Industry 4.0”. We have invested in technology and know-how to integrate in the most effective way our physical production systems with digital technology, thanks also to sophisticated systems of control and management of the machinery.

Industries

We have a long experience in different industries

The naval sector has allowed Omefa to specialize in the realization of parts made with special steels (AISI 316l, AISI 329a/F51, AISI 329s/F55, titanium, Inconel and other alloys). Examples of products made include monobloc shafts, impellers, joints, shaft sleeves, spacers, ogives for impellers, special screws.

This is the sector from which we derive our core business, within which we were born and specialized. Our customers are leading exporters of bottling lines all over the world. Over time, the company has gained experience on all types of oenological machinery: closure, capsuling, inspection, labeling, filling, rinsing and sterilization systems.

For many years Omefa has been active in the Food Processing sector: our components are inserted in machinery and production lines of important food companies. The target areas in which we operate are PREPARATION, PROCESS MOULDING, HANDLING, PRIMARY PACKAGING, SECONDARY PACKAGING.

In the agricultural sector Omefa has thirty years of experience in the production of components of agricultural equipment such as ploughs, turbo snow, defoliating and shearing machines.